Motor Controls & Automation Wiring in Beaumont, Texas

Integrating Reliable Electrical Systems for Mission-Critical Operations

For over 40 years, A&A Electric Company Of Beaumont has been a trusted electrical contractor serving Beaumont, Texas, and surrounding areas, from Houston to Lake Charles and North to the Lakes. Our team understands the electrical infrastructure demands of Beaumont’s industries — from petrochemical plants and manufacturing operations to industrial facilities and distribution centers. As technology evolves, so does the need for precise, reliable, and code-compliant motor controls and automation wiring.

Beaumont is a city that powers industry, and behind every automated production line or complex HVAC system is a sophisticated motor control network. Whether you operate in Jefferson County’s industrial sector or manage a facility near the Neches River corridor, your electrical systems require expertise that combines technical precision with deep local knowledge. That’s where our Motor Controls & Automation Wiring services come in.

Our licensed electricians deliver tailored solutions that ensure your systems operate safely, efficiently, and in full compliance with Texas electrical codes. From new installations to system upgrades and troubleshooting, we design and implement motor control wiring that meets the demands of modern industrial environments. We’re proud to play a role in keeping Beaumont’s businesses operating smoothly, with minimal downtime and maximum reliability. Trust our team to deliver electrical solutions that propel your operations forward.

Insert SEO Title

Insert content

Our Motor Controls & Automation Wiring Services

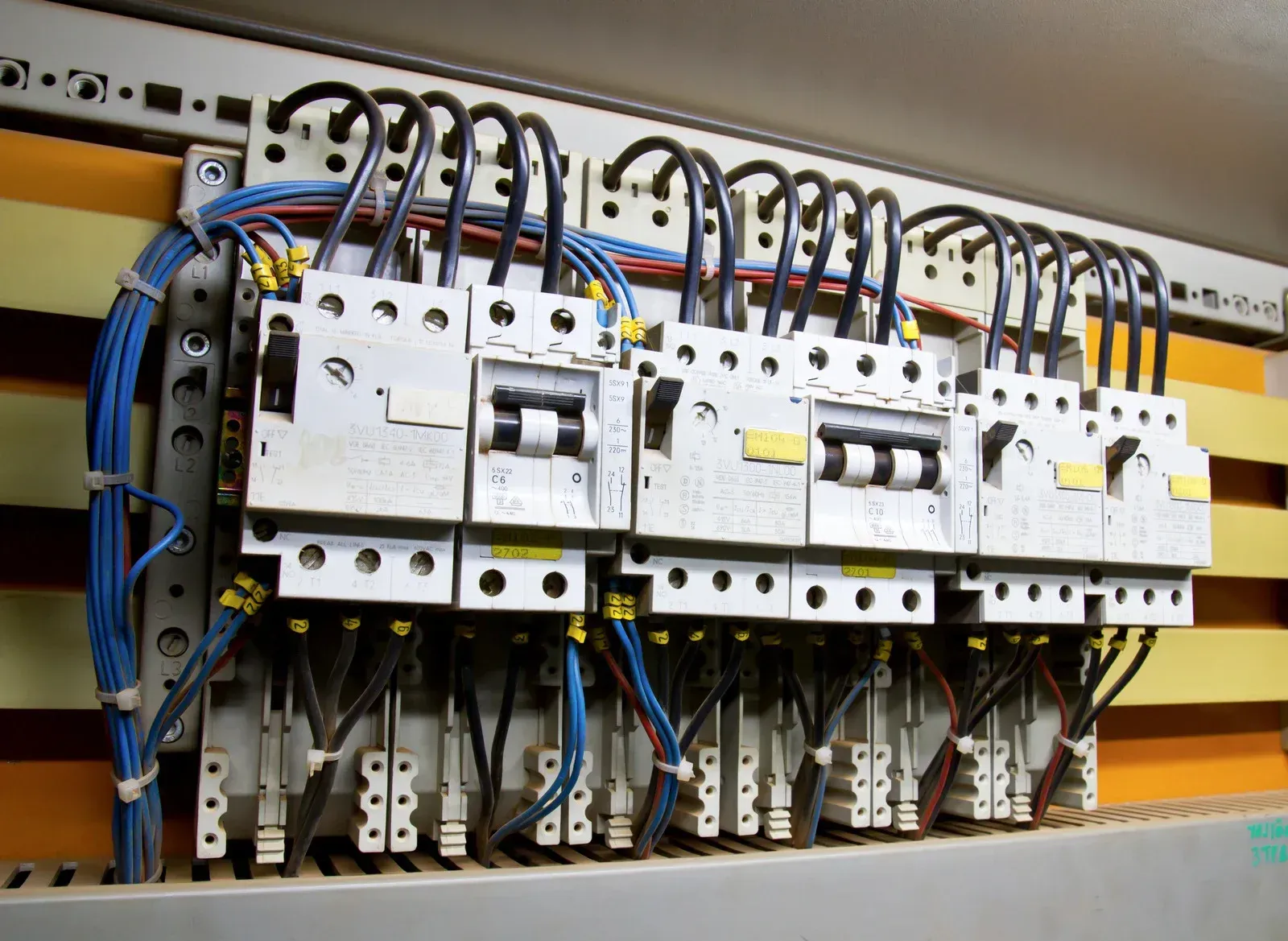

Motor Control Panel Installation

We design, fabricate, and install motor control panels that meet the unique demands of your operation. Our team ensures all panels are built to industry standards, with clear labeling, safe enclosures, and optimal component arrangement. Whether it's a single motor or a complex system, we provide precise control and dependable functionality to support your operations.

Variable Frequency Drive (VFD) Wiring

Our experienced electricians specialize in the proper installation and wiring of Variable Frequency Drives for industrial motors and equipment. VFDs improve energy efficiency, reduce mechanical stress, and provide adjustable speed control. We ensure your VFD systems are safely integrated, properly configured, and optimized for maximum performance and longevity.

PLC (Programmable Logic Controller) Wiring

We deliver expert PLC wiring solutions that ensure seamless automation of your production lines, machinery, and process equipment. Our team implements clean, organized wiring layouts that minimize faults and simplify maintenance. We work with both new installations and existing system expansions, guaranteeing reliable communication between all automated components.

Automation System Upgrades

As technology advances, so should your facility. We provide comprehensive automation system upgrades, modernizing outdated wiring, controls, and equipment. Our upgrades improve energy efficiency, enhance system reliability, and integrate the latest automation technologies. We ensure your facility remains competitive and capable of meeting future operational demands.

Troubleshooting & Repairs

Electrical faults can lead to costly downtime, especially in critical operations. Our team provides rapid-response troubleshooting and repairs for motor controls and automation wiring. Using advanced diagnostic tools, we quickly identify issues, perform targeted repairs, and restore system performance, thereby minimizing disruptions to your operations.

System Design & Consulting

Proper planning is essential for safe, efficient, and scalable electrical systems. We offer specialized consulting and system design services tailored to your facility's operational requirements. From initial assessments to detailed wiring layouts, we provide engineering-driven solutions that optimize functionality, improve safety, and support future expansion or automation.

Benefits of Professional Motor Controls & Automation Wiring

Enhanced System Efficiency and Performance

Professional motor control and automation wiring ensure your systems operate at peak efficiency. Properly installed wiring minimizes electrical losses, voltage drops, and interference, resulting in consistent power delivery to motors and automation equipment. This enhances overall system responsiveness and productivity, especially in demanding industrial environments.

Improved Equipment Longevity

Incorrect or substandard wiring can cause electrical faults, overheating, and premature wear on motors and automated equipment. Professional installation reduces the risk of these issues, helping extend the life of your equipment. By investing in expert wiring, you reduce maintenance costs and protect your long-term capital investments.

Increased Operational Safety

Electrical systems, especially those controlling motors and automation, pose significant safety risks if not properly installed. Certified electricians ensure all wiring adheres to safety codes, grounding requirements, and proper circuit protection standards. This minimizes the risk of electrical fires, equipment damage, and workplace accidents, fostering a safer working environment.

Reduced Downtime and Operational Interruptions

Faulty wiring is a leading cause of equipment breakdowns and unplanned downtime. Professional motor control wiring significantly reduces these risks by ensuring reliable electrical connections and system integrity. With minimized troubleshooting and repair needs, your operations can run smoothly with fewer unexpected interruptions.

Seamless Integration with Modern Automation Systems

Today's industrial operations rely heavily on smart automation, sensors, and control panels. Professional wiring ensures seamless integration between motors, controllers, programmable logic controllers (PLCs), and other automated systems. This enables optimized process control, real-time monitoring, and enhanced overall system functionality.

Compliance with Electrical Codes and Industry Standards

Electrical codes and industry standards exist to ensure the safe and efficient operation of systems. Professional electricians stay up to date with the latest National Electrical Code (NEC) requirements and relevant industry guidelines. Proper motor controls and automation wiring help your facility remain compliant, avoiding costly fines, legal issues, and insurance complications.

Providing the Foundation for Safe and Efficient Automation

Beaumont, Texas, is a city driven by industry, and its facilities depend on reliable, expertly installed electrical systems. As automation becomes increasingly essential across Southeast Texas, having properly designed and installed motor controls and automation wiring is critical to operational success. With over four decades of electrical contracting experience, A&A Electric Company Of Beaumont brings a combination of technical expertise and a deep understanding of the industrial needs of Beaumont, Texas, and nearby areas, from Houston to Lake Charles and North to the Lakes.

We acknowledge the distinct challenges our region faces, including demanding environmental conditions and stringent regulatory standards. That’s why we deliver motor control and automation wiring solutions built to last, keeping your operations efficient, compliant, and ready for future growth

FREQUENTLY ASKED QUESTIONS

What industries in Beaumont benefit from motor controls and automation wiring?

Industries such as petrochemical, manufacturing, food processing, and industrial facilities in Beaumont rely on motor controls for efficient and automated operations. These systems help maintain productivity, reduce manual labor, and ensure consistent performance. Our solutions are tailored to meet the specific needs of industries in Southeast Texas.

Are your motor control wiring services compliant with Texas regulations?

Yes, all our installations strictly adhere to Texas electrical codes and national safety standards to ensure legal and reliable operation. We stay updated on evolving code requirements across Jefferson County. Our team prioritizes safety, functionality, and long-term system compliance.

Can you upgrade existing motor control panels?

Absolutely. We specialize in upgrading outdated panels to improve performance, efficiency, and compatibility with modern automated systems. Upgrades help reduce operational risks, lower energy consumption, and integrate advanced control technologies without major disruptions to your operations.

How do Variable Frequency Drives (VFDs) help my facility?

VFDs enhance energy efficiency and provide precise motor speed control, leading to lower operational costs and extended equipment lifespan. They also reduce wear on mechanical components and contribute to a more sustainable, responsive operation for industrial applications.

Do you offer troubleshooting for existing automation systems?

Yes, we provide prompt troubleshooting and repair services for motor control and automation wiring issues to minimize downtime. Our experienced technicians use advanced diagnostic tools to quickly identify problems and restore optimal system performance with minimal interruption

How long does motor control panel installation take?

Installation timelines vary by project scope, but we work efficiently to minimize disruption while ensuring safe, code-compliant wiring. We conduct detailed planning and testing to guarantee functionality before commissioning your system for full operation.

Is automation wiring only for large industrial operations?

No, automation wiring benefits all sizes, including industrial facilities, by improving system control and operational efficiency. Even smaller operations gain significant advantages through reduced manual oversight and improved equipment performance.

Why choose a local Beaumont electrical contractor for automation wiring?

Local contractors understand Beaumont’s industrial environment and regulatory landscape, providing faster response times and tailored service. Our familiarity with regional requirements and industry expectations ensures your project is completed efficiently and to the highest standard.

HAPPY CUSTOMERS!

What our customers say

Our whole-house generator was installed on Oct 4. Less than 24hrs later on Oct5, we had a 2-hour power outage due to weather. After the prescribed amount of seconds without commercial power, our Generac generator turned on and started running. It ran smoothly with a little noise. Once the power was restored, the generator turned itself off. We're happy customers.

Monica T.

We recently purchased a Generac and are so relieved and grateful to have it! It has already come on during an outage. A & A Electric was recommended to us by others who are long time customers. Their sales and service representatives were excellent.

Cathy E.

Company most courteous to the needs and wants of customers. Great and swift professional install. Will definitely return for future service/installs, and absolutely recommend for your electrical backup (generac) needs and wants.

Juan G.

The electrical crew and the plumbers did a very good job.I'm very pleased with the work they did and they cleaned up after themselves.

William H.

Find us

INQUIRE

Contact Us

We will get back to you as soon as possible.

Please try again later.